Forklift inspections are a cornerstone of industrial safety. They directly impact the operational efficiency and safety of any facility that relies on these versatile vehicles. Regular and thorough inspections help keep all vehicles in optimal condition, minimizing the risk of forklift accidents that can lead to property damage, injury, or worse. Conducting pre-operation checks is a regulatory requirement and a proactive measure that underscores a commitment to safety and can significantly reduce downtime caused by unexpected equipment failures.

This article focuses on the critical aspects of forklift inspections, providing a comprehensive checklist and the specific requirements set forth by the Occupational Safety and Health Administration (OSHA).

Importance of Forklift Inspection

The routine inspection of forklifts is the first line of defense against the hazards these machines can present when improperly maintained. Forklifts operate in dynamic environments where even minor mechanical failures can lead to serious accidents. By identifying and addressing issues through daily inspections, businesses can significantly lower the risk of incidents that endanger workers, disrupt operations, and incur financial losses. Regular inspections reinforce a safety-first culture, the value placed on employee well-being, and operational excellence.

Beyond immediate safety benefits, consistent forklift inspections contribute to the longevity of the equipment. Detecting and resolving small issues before they escalate into major problems can save businesses considerable resources in the long run, avoiding costly repairs and replacements.

Understanding OSHA Forklift Inspection Requirements

OSHA plays a pivotal role in defining and enforcing safety standards in the workplace, including specific guidelines for forklift inspections. According to OSHA regulations, if operated around the clock, forklifts must be inspected at least daily or after each shift. These requirements confirm that all forklifts are in safe operating condition before use. Non-compliance with these standards poses a safety risk and can result in significant fines and legal liabilities for employers.

OSHA's guidelines (OSHA Standard 1910.178) instruct the details for specific aspects of the forklift that must be checked, including but not limited to the condition of brakes, steering, controls, warning devices, and the integrity of the mast and lifting components. Adherence to these requirements helps identify potential mechanical issues or safety hazards that could lead to malfunctions or accidents. Employers must also confirm that inspections are conducted by qualified individuals with the knowledge and expertise to identify issues and accurately assess the forklift's safety.

Daily Forklift Inspection Checklist

The daily pre-operation forklift inspection checklist is a critical tool in maintaining workplace safety. It comprehensively evaluates the vehicle's key components, from physical structures like forks and masts to operational systems, including brakes, steering, and hydraulic controls.

Operators should check for any signs of wear, damage, or malfunction, verifying that everything from the seatbelt to the horn is in working order. This daily routine helps identify immediate safety concerns and contributes to the ongoing assessment of the forklift's condition, guiding maintenance priorities and schedules.

A thorough daily inspection is a preventative measure, reducing the likelihood of accidents caused by equipment failure and reinforcing a culture of safety and responsibility among operators.

Conducting Effective Forklift Inspections

Conducting effective forklift inspections requires a systematic approach and attention to detail. Operators and safety personnel must be thoroughly trained to recognize signs of wear, damage, or malfunction in the forklift's various components. This training enables them to conduct inspections with an eye for detail, so no potential hazard is overlooked. Adopting a consistent routine for inspections, ideally at the start of each shift, establishes a habit of vigilance and responsibility among forklift operators.

Clear protocols and documentation practices also support effective inspections. Using standardized checklists helps confirm that all necessary checks are performed and recorded, which facilitates accountability and allows for the tracking of equipment conditions over time. Open communication channels between operators, maintenance teams, and management are essential for promptly addressing any issues identified during inspections.

Record Keeping and Documentation

Effective record-keeping and documentation are foundational to a robust forklift safety program. Detailed records of each inspection, including the date, inspector's name, and any issues identified, provide a historical account of the forklift's condition and maintenance. This documentation is crucial for compliance with OSHA regulations and serves as a valuable resource for identifying recurring problems or trends that may indicate a need for further training or changes in maintenance practices.

Maintaining accurate and accessible records also supports effective risk management and can be instrumental in the event of an incident investigation. It demonstrates the company's commitment to safety and can be critical in defending against claims or regulatory action. Digital documentation systems offer an efficient way to store and manage these records, making them easily accessible for audits, training, and operational planning.

Leveraging Technology for Forklift Inspections

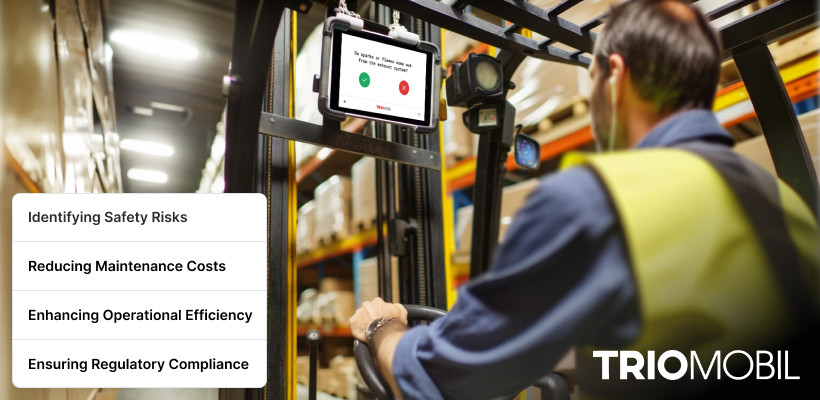

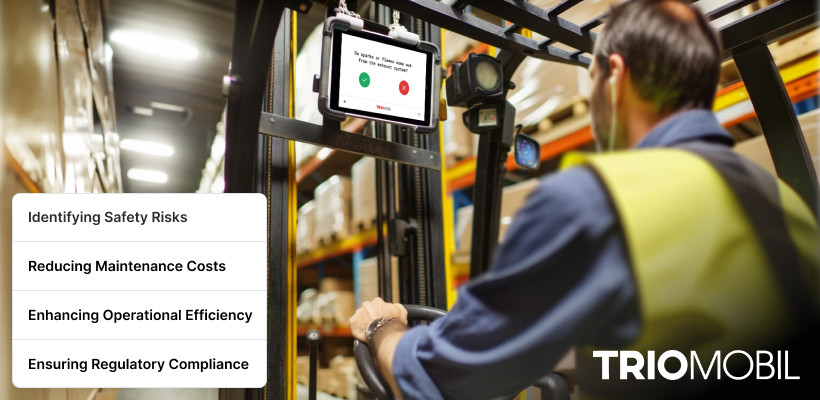

Today, technology plays a significant role in streamlining and enhancing forklift inspections. Deploying forklift safety devices such as a digital forklift safety checklist is a game-changer compared to traditional manual inspections. Digital checklists provide real-time data collection and instant access to inspection records, eliminating the delays and inaccuracies associated with paper-based systems. These checklists can automatically prompt operators to check critical components, providing consistency and thoroughness. In addition, integration with fleet management software allows for immediate reporting of issues, enabling swift corrective actions. The digital format also supports trend analysis and predictive maintenance, significantly enhancing overall operational safety and efficiency.

Trio Mobil's pre-operational safety checklist enhances forklift safety and compliance by requiring operators to pass a safety quiz for full-speed access, with failure resulting in a low-speed mode. This system includes a cloud-driven safety quiz that verifies operator competency and provides real-time reporting. The digital checklist facilitates thorough pre-ops inspections and allows for online safety compliance tracking, promoting continuous improvement in operator safety performance through real-time monitoring and cloud-based reporting.

Beyond Compliance - Enhancing Safety with Advanced Forklift Monitoring Systems

While adherence to inspection checklists and OSHA requirements is fundamental, integrating advanced forklift safety technologies can significantly enhance forklift safety. Systems such as forklift collision avoidance sensors, telematics for real-time monitoring, and automated warning signals can provide additional layers of protection. These technologies assist operators by alerting them to hazards, monitoring vehicle health, and controlling forklift operations in critical situations — helping reduce the risk of incidents.

Implementing such advanced monitoring systems underscores a company's commitment to exceeding basic compliance and prioritizing the well-being of its workforce. While these technologies represent an investment, the potential to prevent accidents and improve operational efficiency offers a compelling return. Embracing innovation in safety technology reflects a forward-thinking approach to workplace safety, setting a standard for excellence in forklift operations.

Trio Mobil offers cutting-edge forklift safety and monitoring solutions designed to enhance safety and operational efficiency. Our systems utilize high-precision Ultra-Wideband (UWB) technology and AI cameras, enabling real-time and accurate detection of pedestrian and MHEs. This technology helps prevent collisions by providing immediate alerts and dynamic speed adjustments, maintaining safe distances between forklifts and pedestrians.

Trio Mobil’s solutions integrate telematics to monitor forklift health and operational parameters continuously. This real-time data collection and analysis enable predictive maintenance, reducing downtime and reducing the risk of potential failures. Our systems also feature zone-based speed control, which automatically adjusts forklift speed in high-risk areas such as intersections and narrow aisles, further enhancing safety.

Leveraging Trio Mobil's Forklift Safety Solutions

At Trio Mobil, we are committed to elevating workplace safety through our innovative solutions, seamlessly integrating with the critical guidelines and best practices for forklift operations and inspections detailed in this article.

Our technology is designed to enhance the safety and efficiency of forklift usage, providing an additional layer of safety and compliance with OSHA standards. With our advanced systems, we offer an effective strategy for reducing workplace accidents and promoting a safer environment for all employees. With a strong commitment to safety and technology, we strive to enhance workplace operations, making them safer and more efficient.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to see how our forklift safety system works.