What is Forklift Tracking?

Forklift tracking refers to the monitoring and management of forklift operations within warehouses, manufacturing plants, and other logistics and supply chain environments. It encompasses various technologies and methods designed to improve the efficiency, safety, and productivity of forklift operations.

Here are some key aspects of forklift tracking:

Forklift Location Tracking

Using high-precision UWB technology for indoor positioning system to know the real-time location of each forklift. This helps in optimizing routes, managing inventory, and providing forklifts are used efficiently.

Forklift Safety Monitoring

Monitoring forklifts for safe operation practices, such as impacts, sudden stops, or near-miss incidents. This can help in reducing accidents and improving worker safety.

Forklift Usage Monitoring

Tracking how and when forklifts are used. This data can be analyzed to improve workflow, allocate resources more effectively, and increase productivity.

How Forklift Tracking Works?

Forklift tracking operates through an intricate network of sensors, data collection tools, and software that together provide a comprehensive view of forklift operations within a facility. At its core, forklift tracking systems employ Real-Time Location Systems (RTLS), Internet of Things (IoT) devices, and various connectivity technologies to monitor the movement and status of forklifts. This information is then processed and analyzed through specialized software platform, offering insights into optimizing routes, scheduling maintenance, improving safety protocols, and enhancing overall operational efficiency.

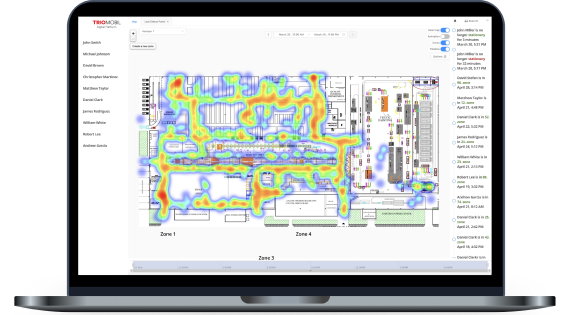

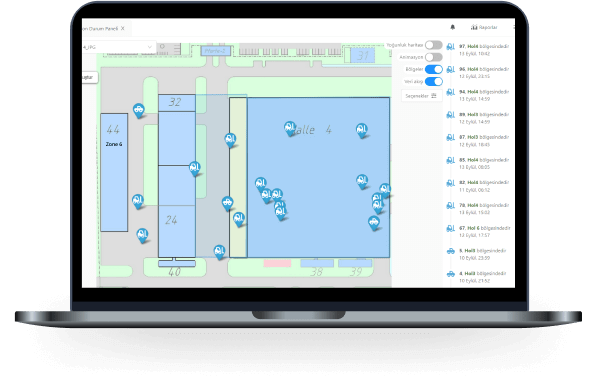

Real-Time High-Precision Forklift Tracking with RTLS

Real-Time Location Systems (RTLS) enable the tracking of forklifts with high precision within warehouses and storage facilities. By utilizing a combination of wireless communication and sensor technology, RTLS provides continuous, accurate location data, allowing for the immediate identification of forklift positions and movements. This technology supports efficient routing and asset utilization, providing that forklifts are always in the right place at the right time.

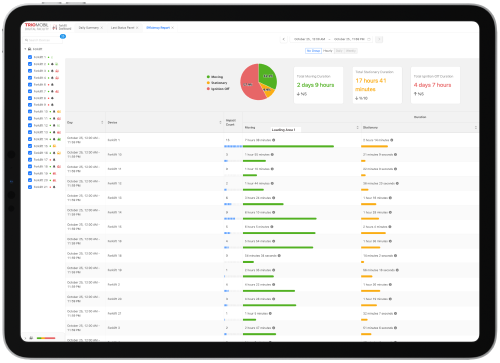

Forklift Monitoring with Detailed Reports

Forklift monitoring systems generate detailed reports on usage patterns, operational efficiency, and maintenance needs. These reports are invaluable for managers, offering insights into daily operations and long-term trends. By analyzing this data, businesses can identify areas for improvement, optimize forklift usage, and plan preventive maintenance to minimize downtime.

Forklift Alert Systems

Forklift alert systems are designed to enhance safety and operational efficiency by providing real-time notifications about potential hazards or unauthorized use. Whether it's an imminent collision, impact, or deviation from designated zones, these alerts enable immediate corrective actions to help prevent accidents and provide compliance with safety protocols.

Forklift Safety with Ultra Wideband (UWB) Technology

Ultra Wideband (UWB) technology significantly improves forklift safety by enabling precise, real-time location tracking within complex and dynamic environments. UWB's high accuracy and reliability in determining the position of forklifts and nearby obstacles or personnel minimizes the risk of collisions and enhances spatial awareness, making it a key technology for safe forklift operations.

Trusted By Leading Brands

AI-powered forklift accident prevention system trusted by industry leaders for exceptional safety and performance.

Benefits of Trio Mobil's System Forklift Tracking System

Real-Time Tracking

Real-time visibility and indoor-outdoor monitoring of forklifts

Extended Battery Life

Rechargeable UWB / BLE tags with up to 7 years of battery life

Ultimate Protection

Alarm system prevents lost assets

Tailor-made Solutions

Personalized solutions for your specific needs

Plug & Play

Quick and easy to install

Automation

Set alerts for specific cases and integrations with 3rd party systems

Data Privacy

End-to-end security

Customized Reports

Tailored reports for your business needs

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!

Frequently Asked Questions

Deployment time can vary based on the system’s complexity and the facility's size, but most solutions offer modular, scalable designs for quick setup and integration.