Workplace Safety with AI Powered IoT Solutions

Forklift Safety & Collision Avoidance

Trio Mobil provides advanced forklift safety systems, integrating AI and UWB technology to improve workplace safety. Our solutions offer comprehensive features such as 360-degree proximity detection, automatic speed reduction, and real-time alerts, designed to reduce the risk of collisions and protect both pedestrians and equipment.

Learn More →

Loading Dock Safety

Trio Mobil's TRUE-AI technology enhances loading dock safety with AI-powered cameras and real-time analytics. It detects pedestrians/trucks, monitors movements, and provides alerts to prevent accidents involving workers and vehicles. Key features include human and vehicle detection and data analytics, which help prevent accidents. TRUE-AI offers a comprehensive solution for a safer and more efficient loading dock environment.

Learn More →

Crane Safety

Trio Mobil's crane safety solutions enhance workplace safety and minimize risks. The TRUE AI system utilizes AI-powered cameras for real-time monitoring of crane operations, while crane warning lights project red signals to alert pedestrians of nearby cranes. These technologies help prevent accidents and promote a safer and more efficient working environment.

Learn More →

Machine Zone Safety

Trio Mobil's Machine Zone Safety Assistance System enhances employee safety with its advanced AI-powered TRUE-AI Video Analytics Camera. This system detects pedestrians and uses geofencing rules to trigger safety measures, including automatic machinery shutdowns, within milliseconds when a pedestrian enters a designated danger zone. Additionally, audiovisual alerts warn pedestrians about active machinery, improving overall safety in machine-operating environments.

Learn More →

Lone Worker Safety

Trio Mobil's Lone Worker Safety Solutions leverage advanced IoT technologies to protect lone workers. These solutions include Wearable Tags with real-time location tracking and emergency alerts, providing constant oversight through IoT connectivity. Additionally, cloud-based lone worker safety alarms offer widespread alerts and immediate responses, detecting inactivity and SOS signals. Utilizing RTLS technology, these systems enable accurate real-time tracking and rapid emergency responses, significantly enhancing safety for lone workers in high-risk environments.

Learn More →

Industrial Efficiency with Cutting-Edge IoT Technology

Forklift Fleet Management

Maximize your forklift fleet's efficiency and safety with FleetBridge's real-time visibility, data insights, and safety protocols. Improve performance by up to 30% with cutting-edge hardware and seamless cloud integration.

Learn More →

Forklift Tracking & Monitoring

Improve forklift safety and efficiency with Trio Mobil's tracking systems. Using high-precision RTLS, these systems provide real-time data on forklift movements, optimize operations, and provide compliance. Key features include real-time tracking, detailed reports, safety alerts, and AI-enhanced monitoring. Customizable for specific needs, these solutions enhance productivity and reduce risks in various environments.

Learn More →

Asset Tracking & RTLS System

Trio Mobil's Asset-Tracking RTLS System offers real-time online asset and inventory management, enhancing efficiency and visibility. With smart tags and connected services, it tracks assets precisely, reduces search times, and prevents product loss. The system supports high production quality by monitoring products through each phase, providing immediate alerts for any anomalies. This comprehensive solution, utilizing technologies like UWB, BLE, GPS, and hybrid tracking, significantly boosts operational efficiency and optimizes workflows in both indoor and outdoor environments.

Learn More →

Maximize Fleet Efficiency with FleetBridge

Elevate your fleet management with FleetBridge and make every decision count. FleetBridge includes:

- Forklift Efficiency Reports

- Operator Access Control

- Pre-ops Safety Checklist

- Impact Detection System

- Real-time Alarms and Notifications

Trusted By Leading Brands

AI-powered forklift accident prevention system trusted by industry leaders for exceptional safety and performance.

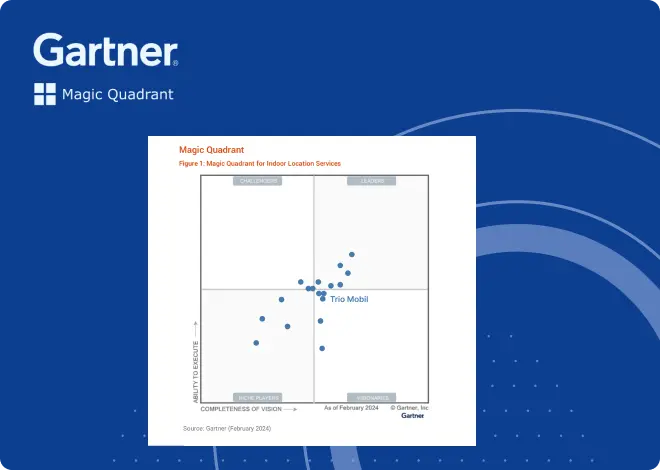

Gartner-Acknowledged Excellence

Gartner has recognized Trio Mobil's outstanding accomplishments and transformative impact on the industry.

Global Coverage

Product Catalogue 2025

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.