Forklift safety is crucial in industrial environments, where these powerful machines play a vital role. Ensuring safety involves a combination of practical strategies and best practices that can effectively minimize the risk of accidents. From implementing advanced technologies to conducting thorough training programs and promoting a culture of safety, companies can protect their workforce and enhance productivity. In this blog, we will delve into key approaches that organizations can adopt to uphold high safety standards and prevent forklift-related incidents.

Incorporating forklift safety into strategic planning underlines its significance beyond mere compliance; it is a cornerstone of operational excellence. Emphasizing safety demonstrates to stakeholders the company's commitment to productivity and the well-being of its employees, paving the way for a sustainable business model. A strong safety record can significantly enhance a company's reputation, making it an employer of choice and a reliable partner for clients who prioritize responsible practices.

Building a Comprehensive Safety Strategy

A comprehensive safety strategy for forklift operations begins with understanding the specific risks and challenges associated with forklift use, such as the potential for collisions, falls, and mechanical failures.

This strategy should incorporate AI and IoT technologies, regular risk assessments, employee training programs, and a continuous improvement process. By integrating advanced AI and IoT solutions, businesses can enhance their safety measures through real-time accident prevention systems, leading safety indicators, and automation. Setting clear safety objectives and involving employees at all levels ensures a dynamic and effective safety plan that addresses current safety concerns and creates a safer and more effective workplace.

Creating a Safety Culture

Creating a safety culture requires consistent effort and engagement from every level of the organization. It involves more than just adherence to safety protocols; it's about fostering an environment where safety is ingrained in every action and decision.

Regular safety meetings, open discussions about safety challenges, and a system that encourages reporting hazards without fear of reprisal are key elements in building a strong safety culture. This culture is fundamental upon which effective forklift safety tips, practices and protocols are built.

Digitalization Impact for Risk Analysis and Management

Record Safety Statistics and See Leading Safety Indicators: Effective risk assessment and management involve a detailed workplace analysis to identify potential hazards for forklift operations, such as areas with high pedestrian traffic or locations prone to congestion. By leveraging digital tools, organizations can record safety statistics and monitor leading safety indicators, providing a comprehensive view of workplace safety.

Hazard Identification and Controls: Once identified, these hazards must be addressed through engineering controls, such as redesigning workflow to minimize forklift and pedestrian interaction, and administrative controls, like scheduling forklift operations during low-traffic periods. Regular reviews and updates to risk management strategies help them remain effective as operations evolve and new risks emerge.

Enhanced Risk Management Strategies: By integrating digitalization into risk analysis and management, organizations can enhance their ability to identify, assess, and mitigate risks. This approach ensures a safer and more efficient workplace for forklift operations, allowing for the dynamic allocation of resources to areas of highest need and optimizing the impact of safety interventions. Regularly updated digital records of safety statistics and leading indicators ensure that strategies remain effective as new risks emerge and operations evolve.

Effective Communication and Training

Effective communication and comprehensive training are pivotal in providing forklift safety. Training programs should cover operational best practices, safety regulations, and emergency response procedures. They should be tailored to the experience level of each operator, with novice operators receiving more in-depth instruction.

Regular refresher courses help keep safety front and center, while open lines of communication allow safety concerns and suggestions for improvement to be heard and addressed promptly.

Enhancing Forklift Safety with Proactive Measures

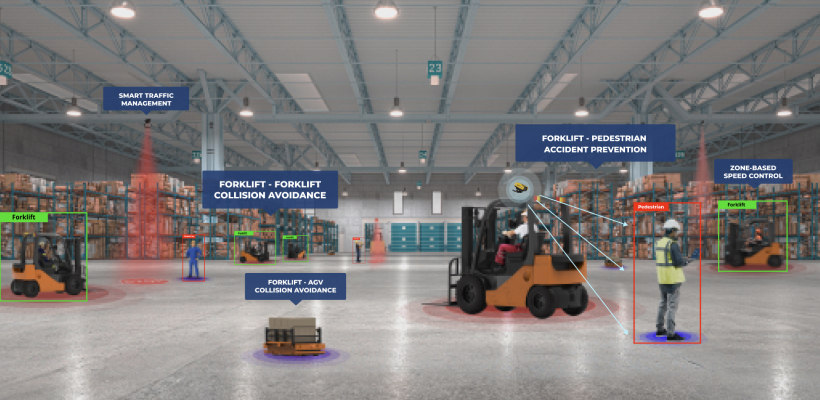

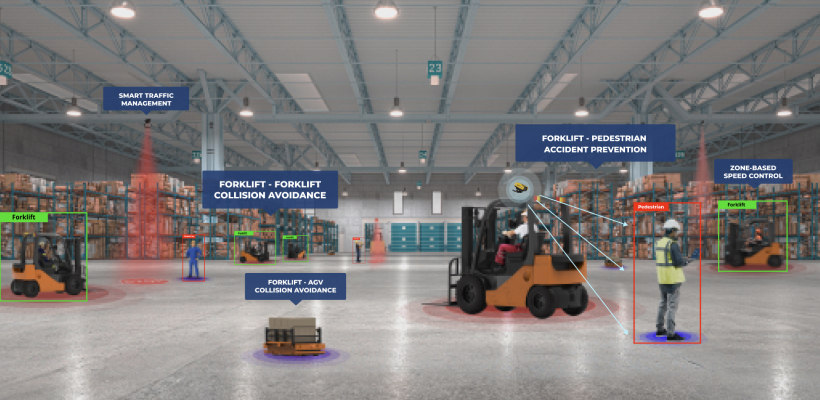

Advanced Technologies: Advanced technologies such as IoT sensors and AI cameras play a vital role in this preventive strategy. These solutions provide accident prevention with high-precision pedestrian detection and proximity detection. Zone-based safety is another important aspect where these technologies enhance safety by monitoring and controlling forklift operations in designated areas.

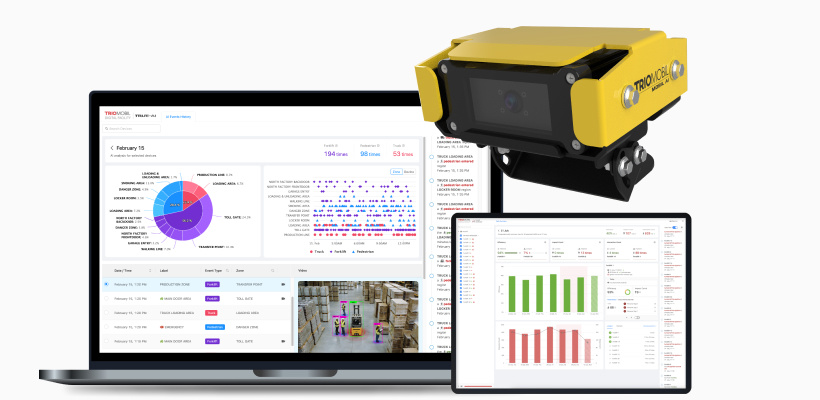

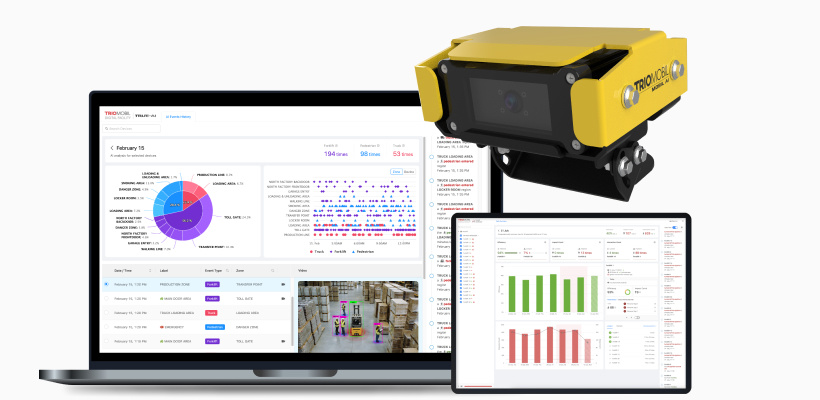

Trio Mobil's Comprehensive Solutions: Trio Mobil integrates cutting-edge high-precision IoT sensors, AI cameras and cloud system into its comprehensive safety solutions to enhance forklift safety. Our systems continuously monitor the environment for proximity of any nearby pedestrians or MHEs. They can immediately slow down the forklift, create real-time alerts, and prevent accidents.

Innovative Strategies for Integrating Safety into Work Processes

Integrating safety into work processes and the physical design of the workplace can significantly mitigate risks associated with forklift operations. This might involve redesigning the layout to provide clear visibility for forklift operators, implementing physical barriers to separate pedestrian and forklift traffic, and designing shelving and storage methods to prevent load instability.

Adopting innovative strategies in safety-integrated work processes means leveraging technology to dynamically enhance forklift safety. Smart workspace technologies, such as UWB anchors and AI cameras, proactively adjust to the forklift's operation, improving visibility and reducing the risk of accidents. Integrating IoT devices to monitor and respond to environmental conditions provides that both forklift operators and the surrounding workspace are part of a connected ecosystem, prioritizing safety through technological innovation.

Digital Wearables: The Future of Personal Protective Equipment (PPE)

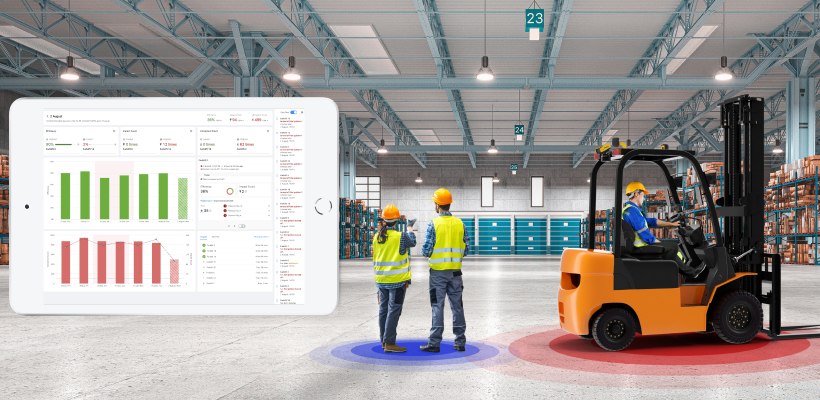

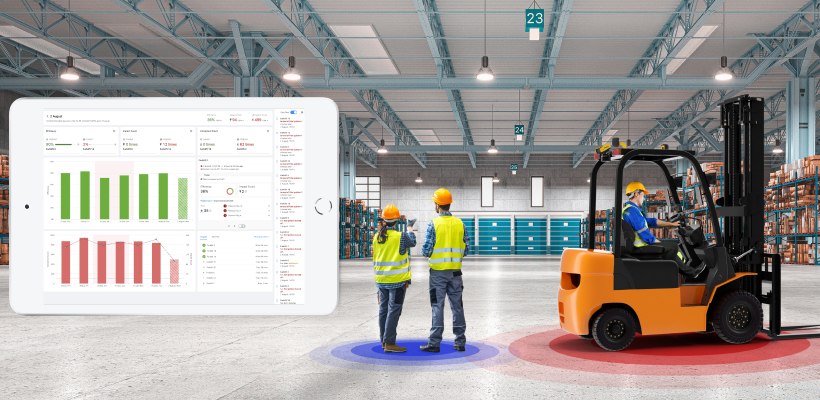

Personal Protective Equipment (PPE) is also evolving with digital advancements, bringing a new layer of safety to forklift operations. Smart or Digital PPE, integrated with sensors and wireless connectivity, actively enhances situational awareness for forklift operators and nearby personnel. Wearables like UWB tags in different forms alert wearers to potential hazards and facilitate real-time communication between operators and pedestrians, significantly reducing the likelihood of collisions.

Safety Performance Monitoring with AI Vision

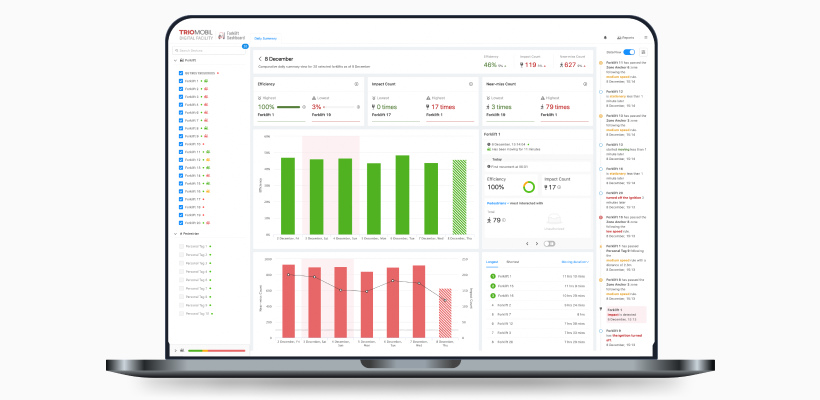

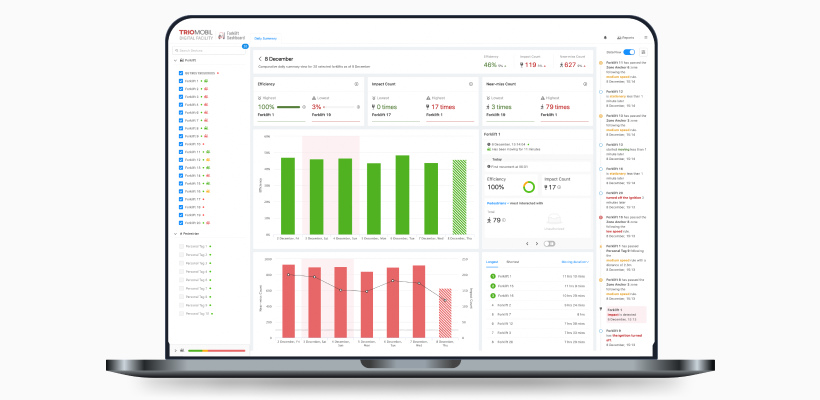

Utilizing AI Vision Insights for safety performance monitoring revolutionizes how organizations manage workplace safety. By tracking specific, measurable KPIs, AI Vision Insight allows for real-time analysis of safety data, enabling organizations to identify unsafe practices or incident trends and adjust their strategies proactively.

This AI-driven approach facilitates targeted interventions by providing precise insights into potential risks and areas for improvement. It fosters a culture of continuous improvement and helps justify investments in safety training, equipment, and technology by demonstrating clear, data-backed benefits.

Trio Mobil uses sophisticated machine learning algorithms to analyze potential risks based on historical and real-time data. This capability allows for proactive interventions, making safety measures timely and effective. The system's real-time monitoring and automated reporting features keep relevant stakeholders promptly informed about safety performance, facilitating swift decision-making and corrective actions.

Integrating Technology with Safety Protocols

Integrating technology into safety protocols represents a significant leap forward in enhancing forklift safety within modern warehouses and manufacturing environments. The advent of forklift telematics has transformed how forklift operations are monitored and managed, providing real-time insights into every aspect of forklift usage. These systems can track forklift movements, operator behavior, and even forklift health, identifying patterns that may indicate unsafe practices such as excessive speeding, sudden stops, or deviations from authorized zones. By alerting managers to these issues, interventions can be made before accidents occur.

Forklift collision avoidance systems have become an indispensable tool in helping to prevent accidents. Utilizing a combination of sensors, UWB devices and AI cameras, these systems can detect any pedestrian or MHE in the forklift's path. Upon detection, operators are immediately alerted through visual and auditory signals, allowing them to take corrective action swiftly.

Wearable devices for forklift operators and pedestrians introduce another layer of safety by monitoring the proximity between forklifts and individuals. These devices can vibrate to warn both parties of potential close encounters, fostering a heightened awareness of each other's presence. This is particularly beneficial in busy or noisy environments where visual or auditory cues might go unnoticed.

Implementing Trio Mobil's Forklift Safety Systems

Trio Mobil's forklift safety systems represent a cutting-edge solution to common safety challenges in forklift operations. By implementing systems that enhance visibility, improve communication, and provide actionable data, businesses can take a proactive stance on safety.

These systems should be integrated thoughtfully into the existing safety culture, complementing and enhancing rather than replacing foundational safety practices. The successful implementation of these technologies requires careful planning, training, and ongoing evaluation to maximize their impact and confirm they contribute to a safer and more productive workplace. Trio Mobil's dedicated team helps in every step of the process, from assessing the safety needs to implementing the solution.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to see how our forklift safety system works.